Isuzu 6HK1 Fire Rescue Vehicles, also named Isuzu fire service truck, If a Isuzu rescue fire truck engine overheats, the following areas should be checked first:1. Cooling system: Problems such as a damaged fan, clogged radiator, damaged thermostat, or insufficient coolant can all contribute to engine overheating.2. Oil quality and quantity: Poor oil quality or insufficient oil can also cause engine overheating.3. Mechanical failures such as cylinder blowout, cylinder liner cracks, or cylinder liner cracks can also cause this phenomenon.

As a heavy-duty diesel powertrain, the Isuzu 6HK1 engine requires strict adherence to technical specifications for maintenance. Key points are as follows:

1. Structural Understanding and Disassembly and Assembly Specifications

Crankshaft-Connecting Rod Mechanism

The cylinder liner features a loose-fit design, requiring special tools to prevent it from falling out during disassembly and assembly. The standard clearance is 0.122–0.156mm.

The piston outer diameter has a tight tolerance (114.894–114.909mm). During installation, pay attention to the piston ring opening direction and the "three clearances" (end clearance, side clearance, and back clearance) adjustment.

The lower crankcase is a one-piece structure and must be hoisted during maintenance to prevent deformation.

Timing System Alignment

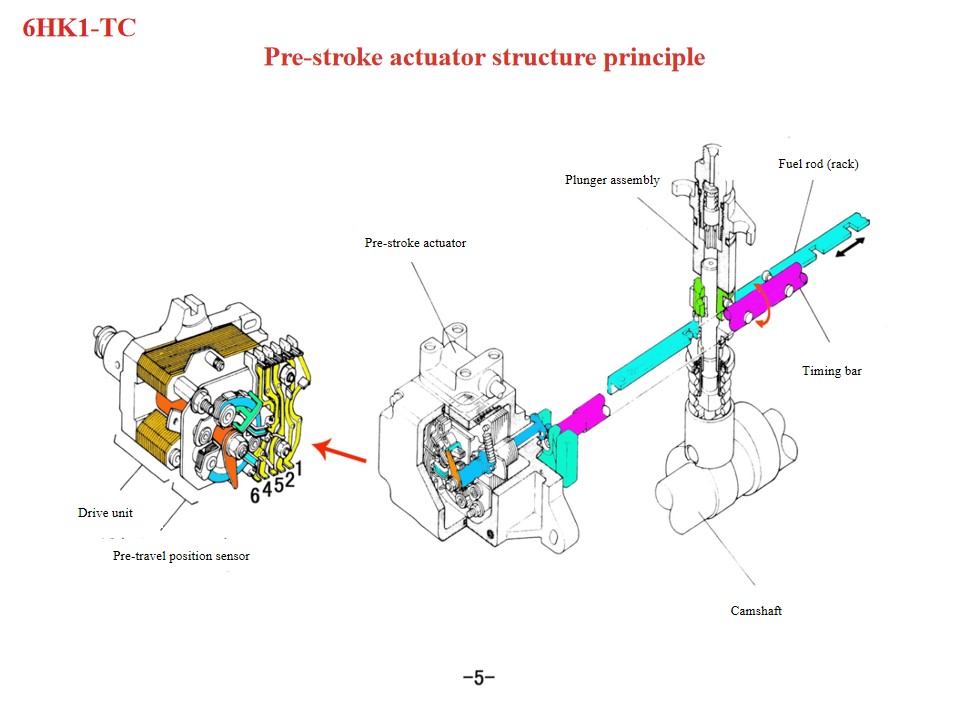

During gearbox assembly, align the crankshaft gear and idler gear marks. The camshaft B mark must be flush with the cylinder head surface. The engine should be at compression top dead center on the first cylinder.

When installing the fuel injection pump, align the timing pointer with the S point on the connector, and align the injection advancer mark with the pump body pointer.

2. Key System Maintenance Points

Lubrication and Cooling System

Oil change interval: Mineral oil: every 5,000 kilometers or six months; synthetic oil: 8,000–10,000 kilometers.

The cooling water inlet is a stepped design and requires disassembly in sequence for maintenance. Antifreeze should be changed every two years or 40,000 kilometers.

Fuel and Air Intake System

Replace the diesel filter every 20,000 kilometers or when the warning light illuminates. Check the air filter every 15,000 kilometers.

The fuel system requires regular cleaning to prevent impurities from affecting injection accuracy.

3. Maintenance Procedure and Precautions

Tool and Data Preparation

Use a torque wrench to tighten bolts (such as the injection pump bracket bolts) according to the manual specifications.

Before repairing, consult the "4HK1-6HK1 Engine Service Manual" (page 332) for detailed parameters.

Fault Diagnosis Logic

First check the status of the "three filters," then troubleshoot the electronic control system (such as the ECU signal). Wear parts should be replaced according to the "Three Stages of Friction" theory.

4. Maintenance Interval Recommendations

Daily Maintenance: Check the engine oil and filter every 5,000 kilometers, and perform a comprehensive inspection every 10,000 kilometers.

Intensive Maintenance: Clean the fuel system and replace the transmission and axle oil every three years or 90,000 kilometers.

You may be interested in the following information