The ISUZU Foam Fire Truck is a high-efficiency firefighting vehicle specifically designed to combat Class A (solid fires), Class B (liquid fires), and mixed fires. Built on the high-performance ISUZU chassis, it integrates the core functions of a water tank fire truck while adding a foam fire suppression system. This system utilizes a foam proportioning device to mix water and foam concentrate in precise ratios, forming a highly covering and long-lasting foam extinguishing agent. This significantly enhances the efficiency of extinguishing flammable liquid fires, such as those involving oil and chemicals. The vehicle is widely used in high-risk fire scenarios, including petrochemical plants, airports, and warehouses, and features rapid response, operational flexibility, and ease of maintenance.

I. Main Structure of the ISUZU Foam Fire Truck

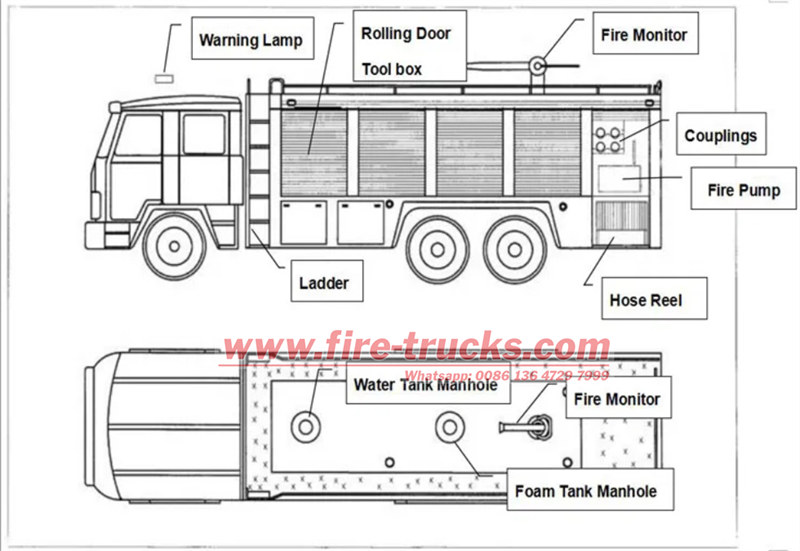

The ISUZU Foam Tanker Fire Truck consists of the following main components: the ISUZU chassis, crew cab, tank, pump and piping system, power take-off and transmission device, additional cooler, auxiliary electrical system, firefighting equipment and fixtures, foam mixing system, and an air foam-water dual-purpose cannon (as shown in the figure below). Among these, the chassis, crew cab, tank, power take-off and transmission device, additional cooler, auxiliary electrical system, and firefighting equipment and fixtures are identical to those of a water tank fire truck.

The key difference between the ISUZU Foam Fire Engine and a water tank fire truck is that the foam fire truck is equipped with a foam tank and a foam proportioning system. The foam fire truck primarily consists of a foam proportioner, pressure water piping, foam concentrate inlet/outlet piping, and ball valves. The foam proportioning system is used during firefighting to mix water and foam concentrate in a specific ratio, delivering the mixture to foam-generating devices.

II. Operation of the ISUZU Foam Fire Truck

The operation of the foam fire truck is similar to that of a water tank fire truck, with the addition of foam system operations.

(1) Foam Concentrate Filling

There are three methods to fill the foam concentrate tank of the ISUZU Foam Fire Truck:

1. Directly pouring through the manhole.

2. Using a dedicated foam transfer pump.

3. Using the vehicle’s compressed air to transfer foam concentrate from a barrel.

The steps for the third method are as follows:

• Connect the suction hose, air charging nozzle, tire inflation hose, and fittings.

• Start the engine to ensure sufficient compressed air pressure in the vehicle’s air reservoir.

• Close the air foam proportioner and open the inlet valve to the foam concentrate tank.

• Connect the inflation hose to the charging nozzle to allow compressed air into the foam barrel.

• The foam concentrate is then forced into the foam tank under air pressure.

• Once the barrel is empty, immediately close the air reservoir’s exhaust valve and the foam tank’s inlet valve to prevent excessive air from entering the foam concentrate.

(2) Foam Fire Suppression

1. Using Onboard Foam Concentrate (Internal Suction)

Internal suction refers to drawing foam concentrate from the vehicle’s onboard foam tank via the air foam proportioner. The steps are as follows:

(1) Connect one end of a hose to the pump outlet and the other to an air foam nozzle.

(2) Set the air foam nozzle’s control lever to the "mixture" or "water" position.

(3) Start the water pump to supply water.

(4) Open the pressure water valve leading to the air foam proportioner.

(5) Increase engine speed to adjust the centrifugal pump’s outlet pressure to match the nozzle’s rated pressure.

(6) Adjust the proportioner’s handle to align the pointer with the indicator value corresponding to the total flow rate of the foam nozzles/cannons in use.

(7) Open the foam concentrate inlet valve, allowing the proportioner to continuously draw foam concentrate at the set ratio.

2. External Foam Concentrate Suction

External suction refers to drawing foam concentrate from an external barrel. The steps are as follows:

(1) Close the foam tank inlet valve, open the external suction port cover, and connect the external suction hose to a foam concentrate barrel.

(2) Open the air charging nozzle to equalize pressure in the barrel with atmospheric pressure, then follow the internal suction steps.

(3) General Precautions for ISUZU Foam Fire Truck

In addition to the precautions for water tank fire trucks, foam fire trucks require the following:

a) When using the air foam mixing system, domestic fire trucks must use natural water sources or water from the onboard tank—never pressurized water directly. The pump outlet pressure should be adjusted to 0.7–1.0 MPa.

b) When using pressurized water sources (e.g., hydrants or relay supply), the water must first be diverted into the tank for pressure reduction.

c) When discharging foam, adjust the proportioner’s pointer to match the nozzle/cannon’s flow rate, ensuring the correct mixture ratio. For 3% foam concentrate, halve the pointer value.

d) When using pressurized water sources, do not open foam system valves before priming the pump or discharging water.

e) After foam use, thoroughly flush the system. Clean the foam tank every six months to remove sediment and apply anti-corrosion treatment. Cleaning method: Close the foam suction valve, start the pump (0.1–0.2 MPa), open all other valves, and flush all foam-mixed water pathways.

III. Maintenance and Troubleshooting for ISUZU Foam Unit Fire Trucks

Common foam system failures include:

1. Foam nozzles discharging only water or intermittently stopping foam discharge.

2. Abnormal foam quality.

The causes and solutions are summarized in the table below:

|

Fault Phenomenon |

Possible Causes |

Solutions |

|

Abnormal foam quality |

1. Mismatch between proportioner suction rate and nozzle/cannon rating. |

1. Adjust proportioner valve to specified value. |

|

2. Nozzle/cannon air intake blocked. |

2. Clear blockage. |

|

|

3. Foam generator mesh damaged. |

3. Repair or replace mesh. |

|

|

4. Foam concentrate degraded. |

4. Replace foam concentrate. |

|

|

No foam discharge (only water) |

1. Foam proportioner not opened. |

1. Open proportioner. |

|

2. Water source pressure > 0.05 MPa, preventing foam suction. |

2. Use water source with pressure < 0.05 MPa. |

|

|

3. Foam tank vent blocked. |

3. Clear blockage. |

|

|

4. Foam tank air charging port closed. |

4. Open charging port. |

|

|

5. Foam suction line valves closed or blocked. |

5. Open valves or clear blockage. |

|

|

6. Suction hose loose or gasket damaged/missing. |

6. Tighten or replace gasket. |

You may be interested in the following information