Fire rescue truck fire pump CB10 140 As core equipment in firefighting systems, fire truck centrifugal pumps are widely used for their efficient water delivery and diverse firefighting needs. With their high flow rates and high lift, centrifugal pumps are widely used in conventional firefighting scenarios, such as urban firefighting and building fires.

Tanker Capacity:

140L/SEngine Power:

520HpFire Pump:

CB10/140-XZFire Monitor:

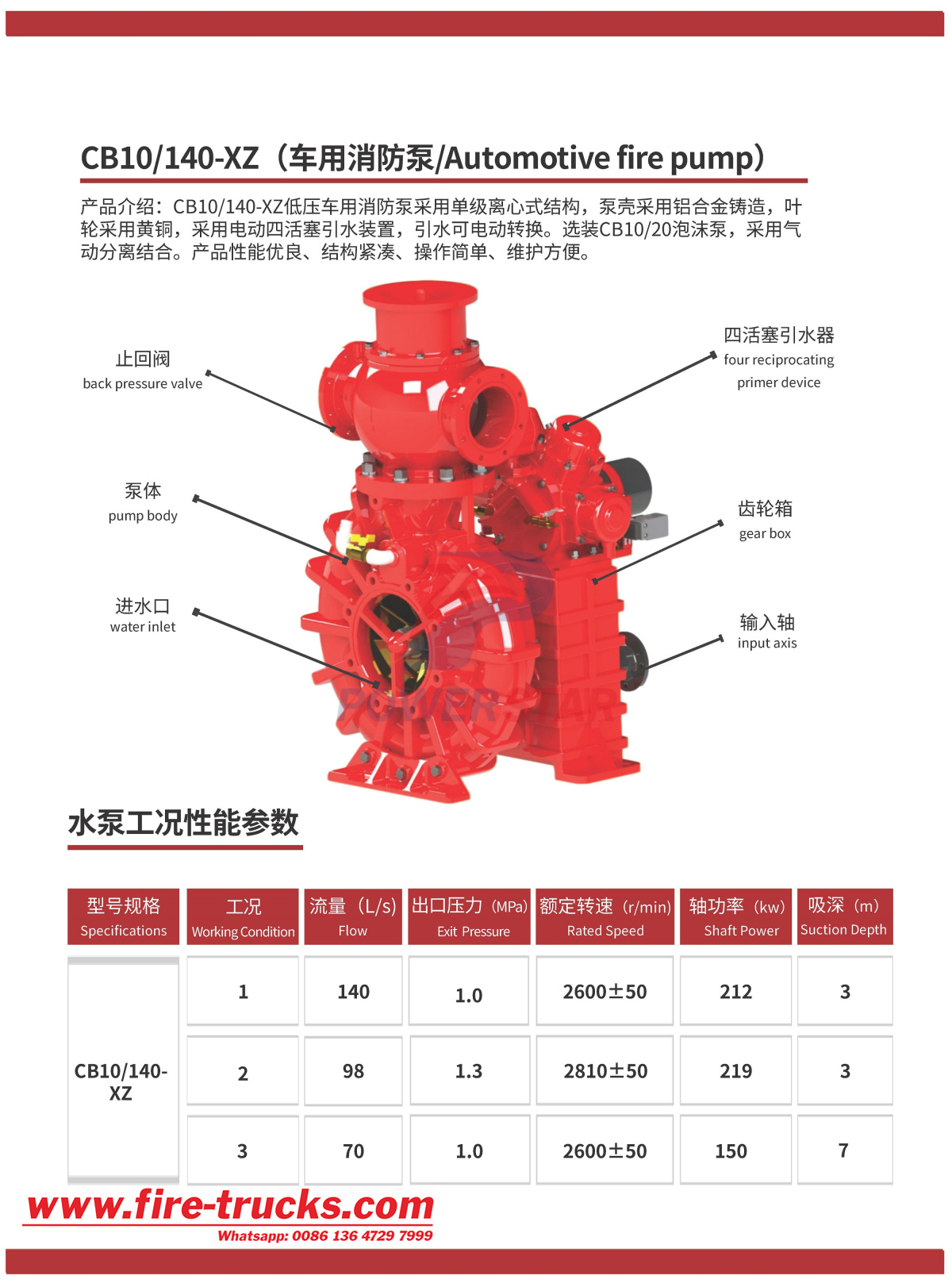

PL8/64Rescue Fire Truck Fire pump CB10/140-XZ, also named Fire engine pump CB10/140 or CB10/140 for fire fighting truck. Model CB10/140 Fire truck centrifugal pumps are used in a wide range of scenarios, including routine firefighting, special firefighting, high-rise water supply, and emergency flood drainage. Their performance advantages, such as flow regulation and continuous water supply, make them a preferred option for firefighting systems.

As a core component of firefighting systems, fire truck centrifugal pumps CB10/140 are widely used due to their efficient water delivery capabilities and the diverse needs of firefighting scenarios. With their high flow rate and high head, centrifugal pumps are widely used in routine firefighting scenarios, such as urban firefighting and building fires. For example, fire trucks use centrifugal pumps to rapidly draw water and deliver it to the fire scene, collaborating with fire hoses to achieve direct flow or spray firefighting.

In scenarios requiring high firefighting power, centrifugal pumps are often used in conjunction with plunger pumps: the former provides a stable water supply, while the latter provides high-pressure water delivery.

The working principle of a fire truck centrifugal pump is to continuously deliver water through the rotation of the impeller, generating centrifugal force. Its core workflow is as follows:

Startup Preparation

The pump body and suction pipe must be pre-filled with water to ensure the impeller is completely submerged.

01 Basic Components of a Centrifugal Pump

02 Starting the Motor

03 Impeller Rotation

04 Liquid Flow

05 Liquid Discharge

06 Stable Operation

Energy Transfer

The prime mover (such as an internal combustion engine or electric motor) drives the pump shaft, causing the impeller to rotate at high speed. The blades force the water to follow the impeller's motion. Centrifugal force throws the water from the center to the periphery, significantly increasing its kinetic energy and pressure.

Continuous Water Intake

A negative pressure zone is formed at the center of the impeller. External water, under atmospheric pressure, enters the pump through the suction pipe, forming a circulating water flow.

|

|

| Rescue Fire Truck Fire pump CB10/140-XZ picture price | Rescue Fire Truck Fire pump CB10/140-XZ picture price |

|

|

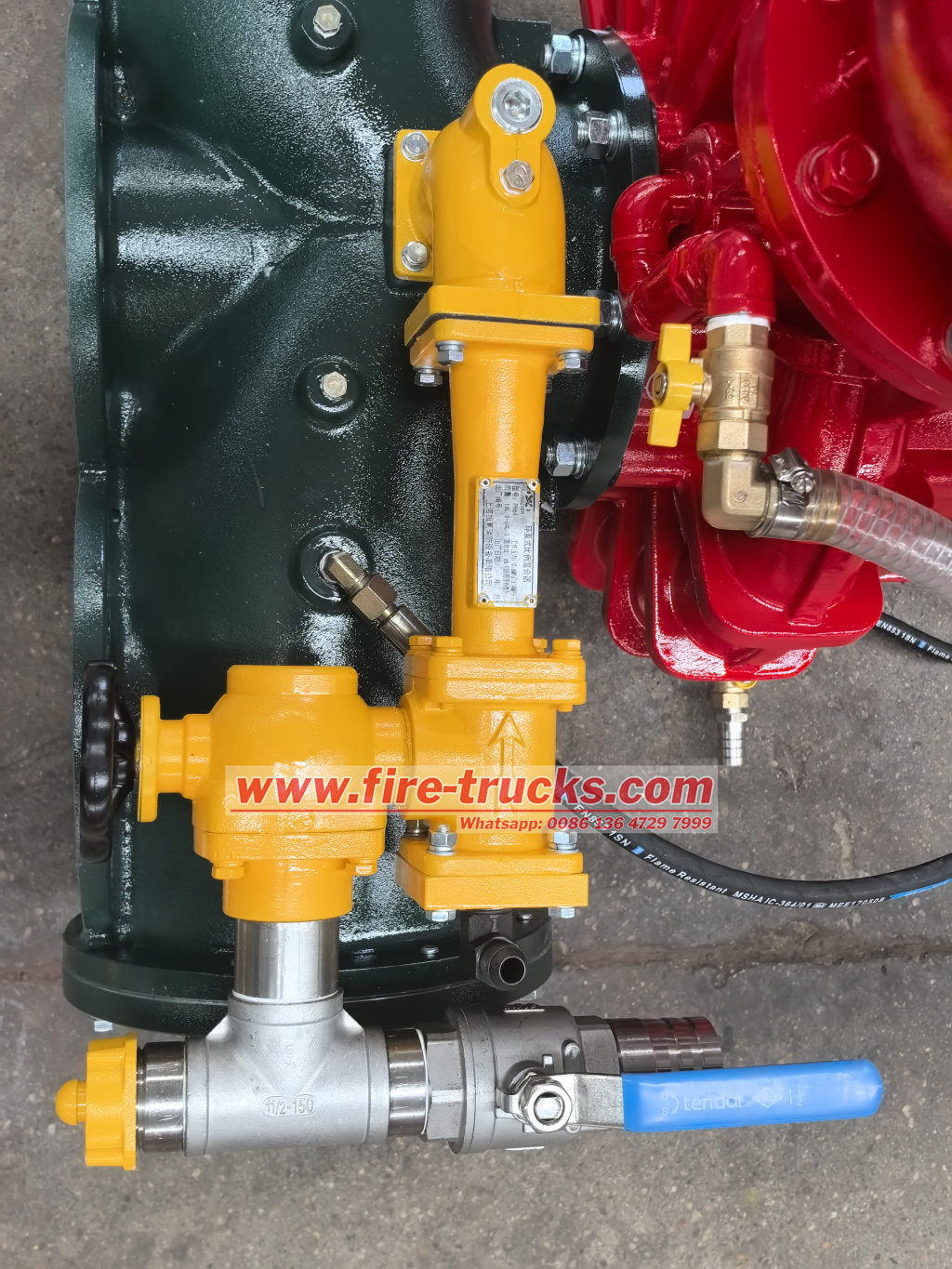

| Fire pump CB10/140-XZ for Isuzu GIGA Fire engine | Rescue Fire Truck Fire pump CB10/140-XZ install Isuzu GIGA chassis |

The advantage of a fire truck centrifugal pump lies in its wide adjustable flow rate and head range, making it suitable for temporary high-pressure requirements at fire scenes.