Moldova brand new 2025 Isuzu 4X GIGA fire pump fire truck quickly arrived at the fire scene with its powerful power system and stable chassis performance. The Isuzu 4KH1 205 horsepower engine equipped on the vehicle ensures rapid response capabilities under complex road conditions and buys precious time for rescue. In this fire rescue, the Moldovan fire department invested in the newly introduced Isuzu GIGA fire truck.

Manufacturer Origin:

PST5170GXFWork capacity :

5,000L water +1,000L foamUpper Body material:

Stainless steelWheelbase:

4500mmAxle drive:

4x2Engine Power:

205hpEngine Model:

ISUZU 4KH1Fire Pump:

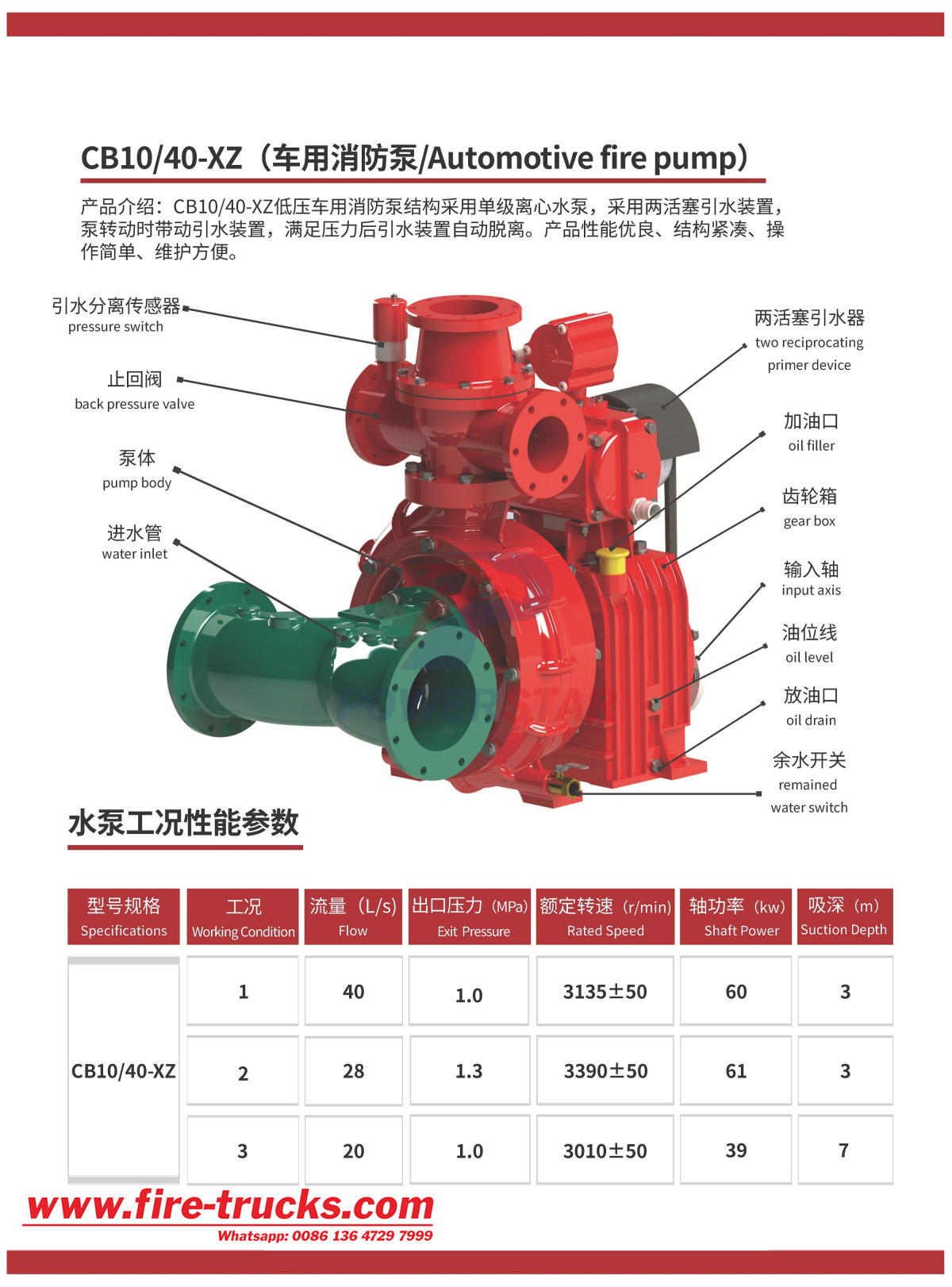

CB10/40XZFire Monitor:

PS30Remark:

Darley fire pump optionalMoldovan customers purchased Isuzu GIGA fire pump fire trucks in batches to comprehensively improve the city's fire emergency response capabilities. In March 2025, a Moldovan municipal government reached a strategic cooperation with a well-known Chinese fire equipment manufacturer Powerstar trucks and purchased a batch of high-performance fire pump fire trucks based on the Isuzu GIGA chassis. This batch of fire trucks uses Isuzu 4X-level GIGA cabs, equipped with Isuzu 4KH1 205 horsepower engines, equipped with 5000L water tanks, 1000L foam tanks, CB10/40 fire pumps, PL32 fire monitors and complete firefighting equipment, aiming to comprehensively improve the fire emergency response capabilities of Moldovan cities and provide stronger protection for the safety of residents' lives and property.

● More than 30 years professional Water Fire truck manufacturer experience.

● Be designed according to your requirements

● We have strong professional design team

● Build strict QC team to guarantee the quality

● Prompt delivery, any order is welcome

● 24 month quality guarantee term

Project Background

As an Eastern European country, Moldova has faced many challenges in fire safety in the process of urbanization in recent years. With the increase in urban population and the expansion of building scale, traditional firefighting equipment can no longer meet the needs of modern cities, especially when dealing with complex scenes such as high-rise building fires and industrial fires. The existing fire trucks and equipment seem to be unable to cope with it. To this end, the Moldovan government decided to introduce advanced firefighting equipment to comprehensively improve fire emergency response capabilities.

The Isuzu GIGA fire pump fire trucks purchased in batches this time have become the first choice of the Moldovan government due to their excellent performance and reliability. This batch of fire trucks can not only meet the needs of daily firefighting tasks, but also play an important role in complex fire scenes, injecting new vitality into Moldova's fire safety cause.

Product Configuration and Advantages

1. Isuzu GIGA Chassis and Cab

The fire truck adopts the Isuzu 4X-level GIGA cab, which is known for its durability, comfort and safety. The cab design conforms to the principles of ergonomics, providing firefighters with spacious riding space and good vision, ensuring that they can arrive at the scene quickly and safely in emergency tasks. In addition, the cab is also equipped with advanced sound insulation and shock absorption systems to effectively reduce noise and vibration and improve driving comfort.

2. Isuzu 4KH1 205 HP Engine

The fire truck is equipped with the Isuzu 4KH1 205 HP engine, which has the characteristics of strong power and high fuel economy. The engine adopts advanced turbocharging technology, which can provide high torque output at low speed, ensuring that the vehicle still maintains excellent power performance under complex road conditions. At the same time, the engine meets the strict European emission standards, and reduces the impact on the environment while operating efficiently.

|

|

|

|

|

TECHNICAL SPECIFICATIONS |

||

|

ISUZU GIGA 4X FIRE PUMP FIRE TENDER |

||

|

1. |

CHASSIS & ENGINE |

|

|

a. |

Engine |

4-Stroke Water Cooled 4 Cylinders-EURO5 205HP |

|

b. |

Gearbox |

Manual Type Model 6 Speed Manual Gear Box |

|

c. |

PTO |

Full Torque, Fly Wheel PTO or equivalent |

|

d. |

Drive |

4 x 2 |

|

e. |

Tyre Size |

10.00 * 20-16 PR |

|

f. |

No. of Tyres |

7 Including one spare tyre |

|

g. |

Steering |

Left Side, Power Steering, Recirculation ball nut type |

|

h. |

Maximum Speed |

Aprox. 90 Km/ h with full load |

|

i. |

Cooling System |

Water Cooled with heavy radiator and thermostat suitable and reinforced for tropical. |

|

j. |

Fuel Tank |

200 Liters |

|

k. |

Front & Rear Bumper |

Heavy duty front and rear bumpers, connected with the chassis frame. One towing hook mounted on rear side. |

|

l. |

Front Axle |

Capacity 6000 kg. 10 Studs |

|

m. |

Rear Axle |

Banjo fully floating, capacity 12000 kg, 10 studs. |

|

n. |

Total GVW |

Approx. 18,000 Kg with specified tires OR equivalent |

|

o. |

Service Brake |

Full Air Brake |

|

p. |

Auxiliary |

Exhaust Brake with pneumatic Control |

|

q. |

Parking Brake |

Mechanical expanded type at rear of transmission |

|

r. |

Voltage |

24 Volt, Traffic installation as per National regulations |

|

s. |

Batteries |

2 * 12V / 115 AH |

|

2. |

CABIN |

|

|

a. |

Doors |

Two lockable doors, with manual roll-down windows |

|

b. |

Seats |

One driver’s seat, fully adjustable, one fixed co driver’s seat with adjustable backrest. |

|

c. |

Dashboard |

The dashboard equipped with all necessary gauges, pilot lamps and switches for operation |

|

d. |

Control |

Control and Pilot Lamp PTO engaged Control including Pilot lamp for LED light Bar and electronic PA System on / off |

|

e. |

Control Box |

All controls and switches for the Public Address System, dashboard mounted within easy reach of the driver or co-driver |

|

f. |

Heating & Cooling |

Standard A/C for driver cabin |

|

g. |

Other |

All necessary Mirrors |

|

3 |

WATER TANK |

|

|

a. |

Capacity |

5000 Litres rectangular Shape |

|

b. |

Material |

Made of Stainless Steel or of Superior Quality material. |

|

c. |

Equipment |

Manhole of Approx. 450 mm dia with quick action cover release and excess pressure safety device Two baffle plates, mounted in the tank’s interior, to prevent a rolling motion of the contents Anti swirl plates to prevent a funnel formation during suction operation. 1 x hydrant Filler inlets, located on the rear side, with 2 ½” Female coupling and make blank caps and equipped with a control valve with strainer. Visual Tank level indicator as a standard design. |

|

4 |

FOAM COMPOUND TANK (WITHOUT CONTENT) |

||||

|

a. |

Capacity |

500 Litres |

|||

|

b. |

Material |

Stainless Steel or of Superior Quality material. and suitable for all types of commercial synthetic and protein foam compounds. |

|||

|

c. |

Equipment |

Manhole of 450 mm Dia with quick action cover release cover release and excess. |

|||

|

5 |

WATER PUMP |

||||

|

a. |

Rated Capacity |

Pressure 750 GPM at 10 Bars or equivalent |

|||

|

b. |

Standard |

Firefighting Centrifugal Pump |

|||

|

c. |

Priming |

Rotary Vane, 24- Volt DC, Electric Priming Pump (imported) |

|||

|

d. |

Construction |

Case and impeller of Cast Bronze Ball Bearing Box of Cast Iron, Duplex Stainless Steel Shaft. Mechanical Seal Type. |

|||

|

e. |

Location |

Truck’s rear compartment |

|||

|

f. |

Suction Inlet |

1 x Flanged suction Inlet Fitted with 4”/ 5” BSS Coupling and Blank Cap. |

|||

|

g. |

Pressure outlet |

2 x 2 ½ “ Pressure Outlet With Globe Valve ( Rear Facing) fitted with instantaneous coupling |

|||

|

6 |

CONTROL PANEL |

||||

|

a. |

Location |

Control Panel at rear side in the pump compartment |

|||

|

b. |

Comprising |

Gauge for normal pressure Vacuum Gauge Priming Pump engagement warning light Hand Throttle switch for RPM engine Control for foam tank suction valve. Control for water tank suction valve. Percentage control for foam system. 2 x 2.5” delivery outlets with Globe Valve Means of Reflecting Stickers. |

|||

|

7 |

QUICK ATTACH HOSE |

||||

|

a. |

1x 30 m high pressure hose (25 mm Ø), mounted on a hose reel in the pump compartment, Manual Crank rewind system with reliable drum brake, with PROTEK Jet / Fog Nozzle (Pistol Grip) |

||||

|

8 |

FOAM PROPORTIONING SYSTEM |

||||

|

a. |

Pro portioner |

Round the Pump (RTP) proportioning system. |

|||

|

b. |

Material |

Gun Metal |

|||

|

c. |

Capacity |

180 LPM |

|||

|

d. |

Foam Mixing Rate |

Foam mixing Rate 0, 1 ….8% |

|||

|

9 |

WATER FOAM MONITOR |

||||

|

a. |

Model |

Suitable for Water / Foam applications |

|||

|

b. |

Output |

1600 LPM |

|||

|

c. |

Performance |

Max. Rotation 360 Degree Max. Elevation +75-15 Degree |

|||

|

d. |

Control |

2” Dia. Valve Fitted beneath the Monitor |

|||

|

e. |

Location |

On the top of the vehicle. |

|||

|

f. |

Operation Ranges |

Foam straight stream throw 45 m Water straight stream throw 50 m |

|||

|

10 |

DRY POWDER INSTALLATION |

||||

|

a. |

One dry powder container, with corrosion protection, holding 250 kg of ABC type compatible dry chemical powder (EU). 5 mm mild steel construction DCP Tank. |

||||

|

b. |

CO2 System |

2 x 45 kg (90 kg) CO2 Cylinder, discharge through 3/8” x 40 m high pressure hose, wounded on Hose Reel with controlled discharge nozzle.

|

|||

|

11 |

ELECTRICAL WARNING EQUIPMENT |

||||

|

a. |

2 x Search light 24 V , 70 w or equivalent Fitted on rear of super –structure 1 LED light Bar (red / red) on top of the cabin roof. 1 Electronic “Wail-yelp” siren with control panel (PA-300), incorporated in Public Address system and 100 W loudspeaker built inside the light bar or equivalent |

||||

|

12 |

PAINTING |

||||

|

a. |

Cab & Superstructure |

Post Office Red |

|||

|

b. |

Frame |

Black acc. (as per manufactured Standard) |

|||

|

c. |

Mudguards, bumper |

Black acc. |

|||

|

d. |

Rims |

Silver acc. |

|||

|

e. |

Light Alloy |

Anodized, unpainted |

|||

|

f. |

Rust Protection |

During all stage of production for use in a salt laden, high humidity atmosphere |

|||

|

g. |

Type Plates |

For GVW, Chassis number, pump etc. |

|||

|

13 |

STANDARD EQUIPMENT / ACCESSORIES. |

||||

|

|

Description |

|

|||

|

a. |

LED light bar with in PA System |

|

|||

|

b. |

Inspection lamp |

|

|||

|

c. |

Suction Hose 4” x 10’ with coupling (Light alloy) |

|

|||

|

d. |

Suction Wrenches |

|

|||

|

e. |

Deliver Hose 2 ½” dia x 100 feet with coupling. Working pressure 18 Bars, busting pressure 50 bars with OEM Supplied BSS Aluminum coupling complete. |

|

|||

|

f. |

Fire Axe, 36-inch long handle |

|

|||

|

g. |

Fire Blanket, 1.2 x 1.2 meters |

|

|||

|

h. |

Search Lights mounted on the vehicle |

|

|||

|

i. |

28/30 Feet Light Alloy Aluminum Ladder (2 Section) Extension type |

|

|||

|

j. |

Suction Strainer with Built in NRV |

|

|||

|

k. |

Branch Pipe with Spray / Fog Discharge Pattern |

|

|||

|

l. |

Standard Tool Kit for Superstructure |

|

|||

|

m. |

PROTEK Multi- Gallonage Nozzle model 366—TO with aluminum branch pipe or equivalent |

|

|||

|

n. |

Bolt Cutter-24 Inches Size |

|

|||

|

o. |

Handheld Light – Rechargeable |

|

|||

|

p. |

Fire suit |

|

|||

|

q. |

Fire Blanket |

|

|||

3. Large-capacity water tank and foam tank

The fire truck is equipped with a 5000L water tank and a 1000L foam tank, which can meet the needs of long-term firefighting operations. The water tank is made of high-strength materials with good corrosion resistance and impact resistance, ensuring safety and reliability in harsh environments. The foam tank is equipped with an automatic mixing system, which can automatically adjust the foam ratio according to the size of the fire to improve the efficiency of firefighting.

4. CB10/40 fire pump

The fire truck is equipped with a CB10/40 fire pump with a maximum flow rate of 4000 liters per minute and a head of more than 100 meters. It can quickly respond to the needs of the fire scene and ensure sufficient water supply. The fire pump adopts an intelligent control system, which can automatically adjust the water pressure and flow according to the size of the fire to improve the efficiency of firefighting. In addition, the fire pump is also equipped with multiple safety protection devices to ensure safety and reliability in high-pressure operations.

5. PL32 fire cannon

The fire truck is equipped with a PL32 fire cannon with a range of up to 80 meters, which can cover a large area of fire. The fire cannon adopts a fully automatic control system, which can automatically adjust the spray angle and water flow intensity according to the size of the fire to improve the accuracy of fire extinguishing. In addition, the fire cannon is also equipped with anti-freeze and anti-blocking functions to ensure that it can still work normally in extreme environments.

6. Complete fire fighting equipment

The fire truck is equipped with complete fire fighting equipment, including demolition tools, lighting equipment, rescue ropes, etc., which can cope with different types of fire and rescue scenarios. These equipment are made of high-strength materials, with good durability and reliability, ensuring maximum effect in emergency tasks.

Significance of cooperation

This batch purchase is not only an important measure for Moldova to improve its fire safety level, but also a model for deepening cooperation between China and Moldova in the field of fire fighting. Isuzu GIGA fire pump fire truck has won the trust of Moldovan customers with its excellent performance and reliable quality, further consolidating the position of Made in China in the international market.

For Moldova, the commissioning of this batch of fire trucks will significantly enhance its fire emergency response capabilities and provide stronger protection for the safety of life and property of urban residents. At the same time, this also provides experience for other Eastern European countries to learn from and promote the upgrading of regional fire equipment.

Future Outlook

With the acceleration of global urbanization, fire safety issues will receive more and more attention from governments. Chinese fire equipment manufacturers will continue to uphold the spirit of innovation, develop more high-performance and intelligent fire products, and provide quality services to global customers. At the same time, the cooperation between China and Moldova in the field of fire protection will be further deepened to jointly promote the progress and development of fire safety technology.