Isuzu 4,000L foam firefighting truck is engineered to combat Class B fires involving flammable liquids (e.g., petroleum, chemicals). Its foam projection system mixes water with fire-suppressing foam at precise ratios, forming an oxygen-blocking blanket to rapidly extinguish liquid fuel blazes. Equipped with a high-capacity 4,000-liter tank and a high-pressure pump, Isuzu 4,000L foam firefighting truck delivers sustained foam discharge rates up to 4,000 L/min, enabling swift control of expansive fire incidents. Its extended-range monitor nozzle projects foam over 60 meters, ensuring operator safety during refinery, warehouse, or wildfire emergencies.

Operational Guide for Isuzu 4,000L Foam Firefighting Truck: Technical Parameters and Procedures

1. Vehicle Overview

The Isuzu 4,000L foam firefighting truck is engineered for rapid response to Class B (flammable liquids) and Class A (solid combustibles) fires. Built on a heavy-duty Isuzu FVR chassis, it features a 6HK1-TCG61 diesel engine with a power output of 176 kW (240 hp) at 2,200 rpm, generating 981 N·m torque. The chassis complies with Euro V emission standards and includes a 9-speed manual transmission for optimal off-road maneuverability.

2. Firefighting System Specifications

3. Discharge Equipment

4. Control and Monitoring Systems

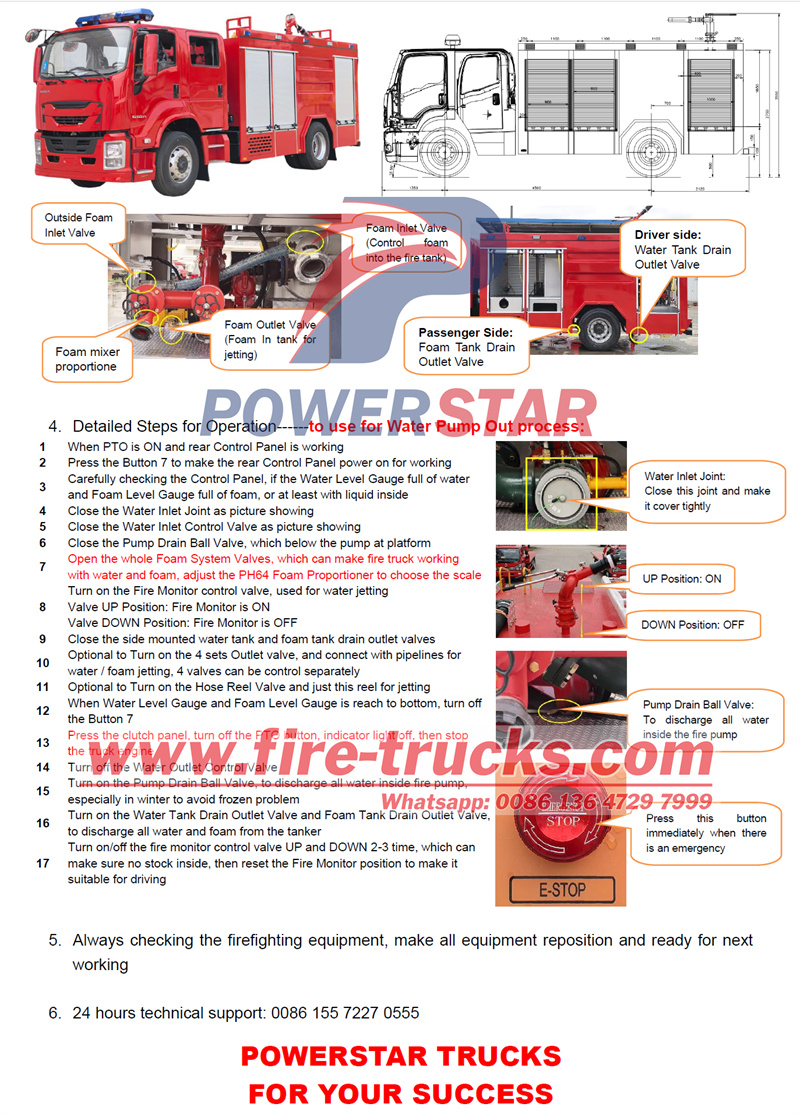

5. Operational Procedure

Step 1: Pre-Deployment Checks

Step 2: Engine and Pump Activation

Step 3: Foam Application

Step 4: Discharge Control

Step 5: Post-Operation

6. Safety Protocols

|

Name |

Water Foam Tank Fire Truck |

|

|

Model |

PT550PM |

|

|

Painting |

Fire red (RAL 3000) (Customer LOGO welcome) |

|

|

Chassis |

Brand |

ISUZU |

|

Chassis Model |

ISUZU GIGA 4X |

|

|

Engine power |

150KW (205HP) |

|

|

4X2 Left Hand Drive, Double Cabin |

||

|

Outline dimension |

8150×2500×3600 mm |

|

|

Gross Vehicle Weight |

18000 kg |

|

|

Number of Seats |

1+1+4 (inc. driver) |

|

|

Fire-extinguishing Agents |

Water (L) |

5000L |

|

Foam (L) |

500L |

|

|

Chemical (L) |

Without |

|

|

Fire pump |

Model |

XIONGZHEN CB10/40 |

|

Pressure (Mpa) |

1.0 |

|

|

Rate (L/s) |

40 |

|

|

Fire Monitor |

Model |

PL36 |

|

Rate (L/s) |

36 |

|

|

Throw Range(m) |

Water ≥ 60, Foam≥ 50 |

|

|

Fire Equipment |

Factory standard |

Special equipment for optional |

You may be interested in the following information